| |

Fluoro(불소수지-Teflon)

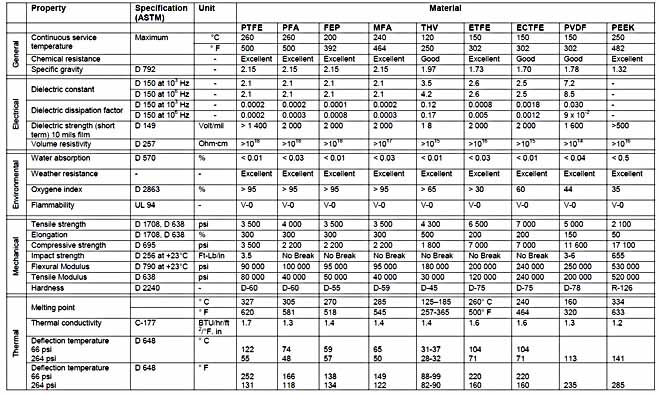

탁월한 내화학성 및 내열성을 가지는 불소수지는 불소화합물의 종류에 따라 매우 다양한 제품들이 있는데 그 대표적 제품으로 PTFE, PVDF, PFA, FEP, PCTFE 등이 있다. 이들 각각에는 제조사마다 독립적인 상표(Trade Name)를 사용하여 다양한 제품을 출시하여 사용하고 있다. 흔히 우리가 아는 Teflon은 DuPont에서 나오는 PTFE의 제품명 이다. 그 특성이 뛰어나고 다양한 가공방법으로 다양제품이 가능하여 산업용 소재에서 부터 후라이팬, 아웃도어코팅용 등 많은 부분에서 사용되고 있다. 순수 PTPE에 다양 첨가제(filler : Glass, Carbon등)를 넣어 독특한 성질의 제품(생고반 Rulon)들도 주요하게 사용되고 있다.

특성(PTFE-PolyTetraFluoroEthyllene)

불소수지의 3대 특징(최고의 내열성 +최고의 내화학성 +비접착성).

높은 내열성 및 넓은 사용온도(-240°C to 260°C)

최고의 내화학성

최고의 내후성(Weather resistance)

최저 수준의 마찰계수

높은 인장성, 내화염성, FDA.

다양한 불수수지 화학명 및 대표 상표명

PTFE, FEP, PFA - Teflon,® Neoflon®, Hyflon®

(Fluorinated ethylene propylene)(Perfluoroalkoxy)

MFA - Hyflon®

ETFE - Tefzel®, Neoflon®(Ethylene tetra-fluoro ethylene)

ECTFE - Halar®(thylene chloro tri-fluoro ethylene)

PCTFE(or CTFE) - Neoflon®(originally Kel-F®)(Poly chloro tri-fluoro ethylene)

PVDF - Solef®, Hylar®, Kynar®(Poly vinyledene fluoride)

Rulon ®

the Saint Gobain Performance Plastics의 고유한 상표명으로 PTFE에 다양한 필러를 독특하게 배합하여 용도별(베어링, 내열, 강도 등) 최고의 성능을 발휘하는 제품으로 LR,J, 641, AR, 142, 123등 많은 제품들이 있다. 비슷한 제품으로 부삭샴반의 Turcite가 있다.

부삭샴반에 나오는 제품은 마모베어링용인 Turcite 이외에도 seal제품은 Turcon과 전기화학 및 고성능 베어링용으로 HiMod가 있다.

TYPICAL PROPERTIES of PTFE

|

ASTM or UL test |

Property |

PTFE

(unfilled) |

PTFE

(25% glass filled) |

PTFE

(25% carbon filled) |

PHYSICAL |

D792 |

Density (lb/in³)

(g/cm³) |

0.078

2.16 |

0.081

2.25 |

0.075

2.08 |

D570 |

Water Absorption, 24 hrs (%) |

< 0.01 |

0.02 |

0.05 |

MECHANICAL |

D638 |

Tensile Strength (psi) |

3,900 |

2,100 |

1,900 |

D638 |

Tensile Modulus (psi) |

80,000 |

- |

- |

D638 |

Tensile Elongation at Break (%) |

300 |

270 |

75 |

D790 |

Flexural Strength (psi) |

No break |

1,950 |

2,300 |

D790 |

Flexural Modulus (psi) |

72,000 |

190,000 |

160,000 |

D695 |

Compressive Strength (psi) |

3,500 |

1,000 |

1,700 |

D695 |

Compressive Modulus (psi) |

70,000 |

110,000 |

87,000 |

D785 |

Hardness, Shore D |

D50 |

D60 |

D62 |

D256 |

IZOD Notched Impact (ft-lb/in) |

3.5 |

- |

- |

THERMAL |

D696 |

Coefficient of Linear Thermal Expansion

(x 10-5 in./in./°F) |

7.5 |

6.4 |

6.0 |

D648 |

Heat Deflection Temp (°F / °C)

at 264 psi |

132 / 55

|

150 / 65

|

150 / 65

|

D3418 |

Melting Temp (°F / °C) |

635 / 335 |

635 / 335 |

635 / 335 |

- |

Max Operating Temp (°F / °C) |

500 / 260 |

500 / 260 |

500 / 260 |

C177 |

Thermal Conductivity

(BTU-in/ft²-hr-°F)

(x 10-4 cal/cm-sec-°C) |

1.70

5.86

|

3.1

10.6

|

4.5

15.5

|

UL94 |

Flammability Rating |

V-O |

V-O |

V-O |

ELECTRICAL |

D149 |

Dielectric Strength (V/mil) short time, 1/8" thick |

285 |

- |

- |

D150 |

Dielectric Constant at 1 MHz |

2.1 |

2.4 |

- |

D150 |

Dissipation Factor at 1 MHz |

< 0.0002 |

0.05 |

- |

D257 |

Volume Resistivity (ohm-cm)at 50% RH |

> 1018 |

> 1015 |

104 |

|